We contribute to solving our customers' problems by utilizing our abundant know-how and global network in the fields of welding, cutting, industrial robots, electronic component manufacturing, semiconductor manufacturing, factory automation, environmental equipment, and machine tools.

Products (FA/Equipment)

We contribute to solving our customers' problems with our extensive product lineup based on our broad network and know-how accumulated over many years, including welding, cutting, industrial robots, automation, environment-related equipment, and various machine tools, mainly for the automotive and electrical machinery industries.

-

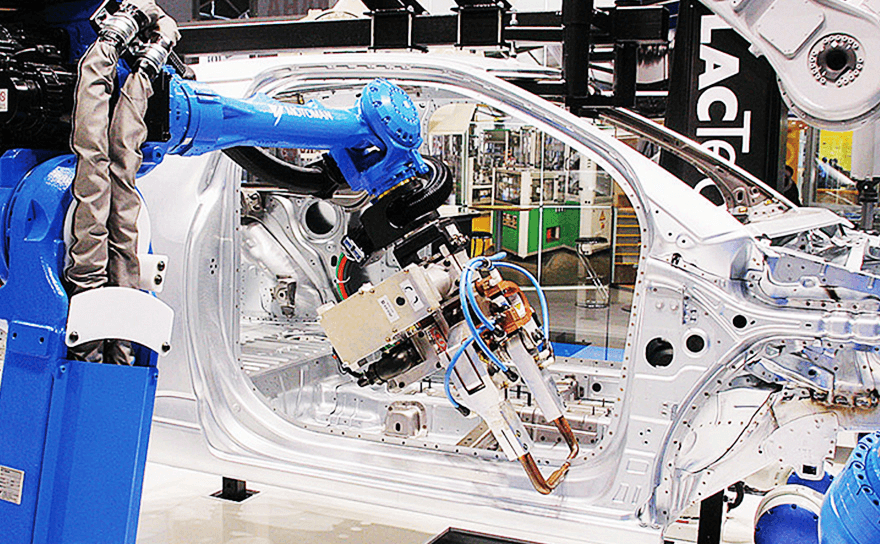

Factory Automation

We provide comprehensive support from installation to management as a system integrator for robot systems, dedicated production lines, and automated warehouses.

-

Consumable goods

We offer a wide range of welding materials, including mild and stainless steel. In addition, we offer welding machines, plasma welders, laser welders, and a variety of other welding-related consumable goods.

-

Engineering Services

We provide solutions from product design to equipment installation to support improved production capacity and enhanced quality.

Our engineers assist with troubleshooting and preventive maintenance to avoid production stoppages and ensure more efficient operations. -

Environmental equipment

We provide solutions that lead to decarbonization and energy savings in the environmental areas of waste gas, wastewater, and recycling.

-

Equipment

We handle a wide range of machine tools and forging machines that match the processing needs of production sites, and we support our customers in selecting the most suitable equipment and labor-saving solutions to meet their needs.

Products (Electronic devices)

We provide sales and maintenance services for machinery and components, mainly for the electronics industry, including semiconductors.

Products handled include various types of bonding equipment, visual inspection machines, reflow furnaces, wet blasting equipment, and abrasives.

-

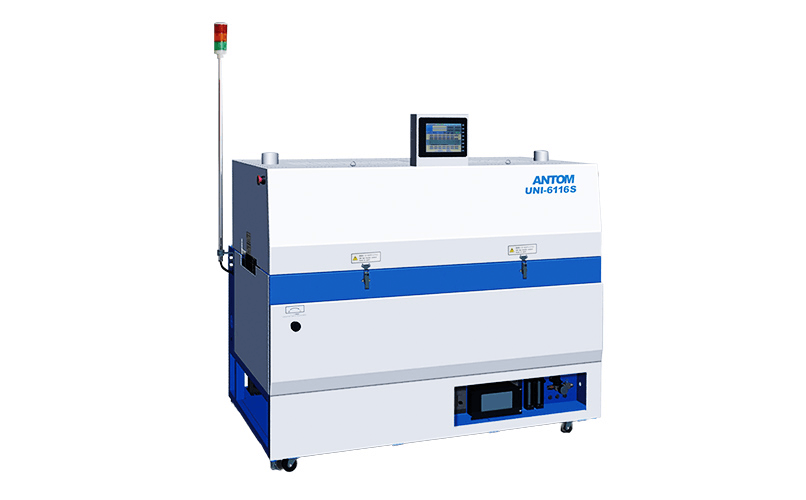

Reflow and screening equipment

Compatible with the industry's smallest reflow of 2 m or less. Specializing in significantly reducing running costs, it is ideal for mass production, high-mix low-volume production, and cell production.

-

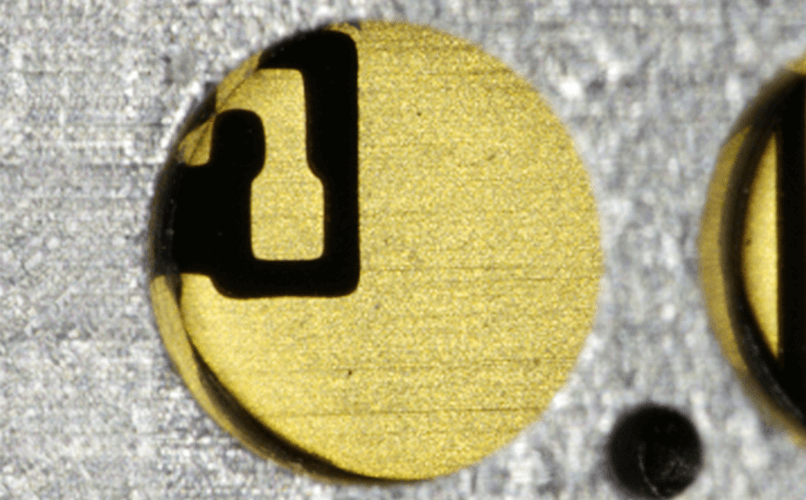

Die bonder

Die bonder for the solder joint process for power devices that require high joint quality.

-

3D wire visual inspection system

This is the visual inspection system realizing automation and efficiency of inspections required in the wire bonding process. Features include highly reliable inspection by high-performance 3D and dimensional measurements, traceability, and easy operation.

-

Deburring Equipment/Wet Blasting

This is a compact, continuously automated machine capable of double-sided processing of strip workpieces. Wide guns are used for electronic components such as printed circuit boards and semiconductors, and both sides are uniformly processed to accommodate small strips and the plates of workpieces.

-

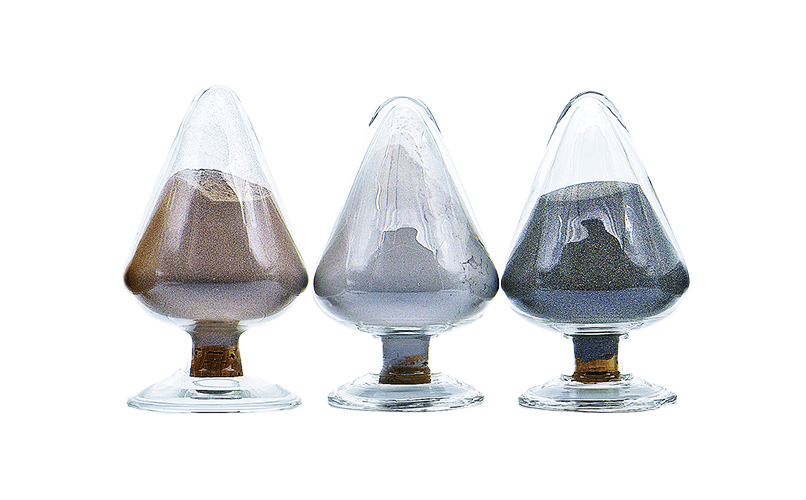

Abrasives

The anchoring effect of time-independent nano-level unevenness and the cleaning power to scrape off any foreign substance on the surface, layer by layer, enables the adhesion of coatings on super engineering plastics, CFRP, metals, ceramics, and other materials regardless of the material of the object.

-

Electronic Circuits (PCB)

We provide electronic circuit boards required for developing next-generation components, such as compact, thin, high heat dissipation, high heat resistance, high efficiency, and UV resistance.

We can offer substrates with unique characteristics not available from other companies by utilizing a dedicated line for small and thin products and jointly developing materials with component manufacturers.